DBU: Applications and Preparation

Introduction

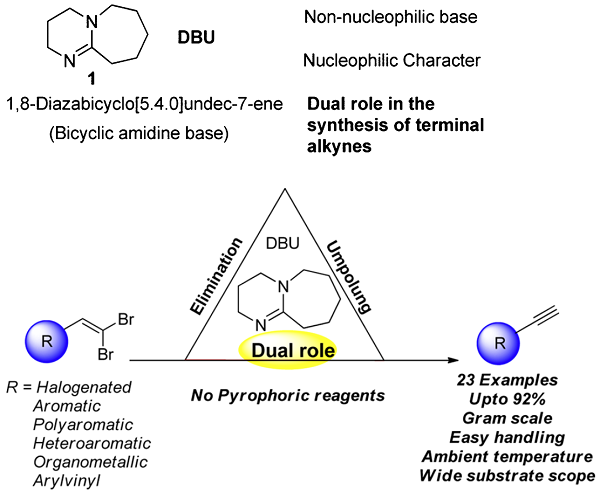

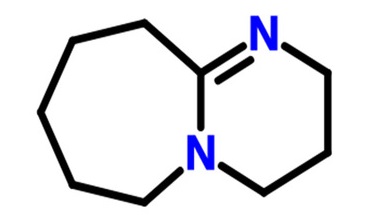

1,8-Diazabicyclo[5.4.0]undec-7-ene (DBU) is a bicyclic organic compound with the chemical formula C9H16N2. It is a colorless liquid at room temperature and is commonly used as a strong base in organic chemistry. DBU has a high basicity due to the presence of two nitrogen atoms in its structure, which make it an excellent catalyst for many reactions including polymerization, esterification, and transesterification. It is also used as a ligand in coordination chemistry and as a solubilizing agent in pharmaceuticals[1].

Figure 1 appearance of DBU

Applications

As mentioned earlier, DBU is commonly used as a base in many organic reactions due to its strong basicity and nucleophilicity. One of the most important applications of DBU is as a catalyst for the synthesis of polyurethanes. Polyurethanes are a class of polymers that have many industrial applications such as foams, coatings, adhesives, and sealants. DBU catalyzes the formation of urethane linkages between isocyanate and alcohol functional groups, resulting in the formation of polyurethane chains.It is also used in the manufacture of certain pharmaceuticals, where it can be used as a base in the synthesis of active pharmaceutical ingredients (APIs). For example, DBU has been used as a base in the synthesis of antihistamines and anti-inflammatory drugs.

In addition to its use as a base, DBU can also act as a solvent for various chemical reactions. Its solubility properties make it useful for dissolving polar and nonpolar compounds in organic reactions. Moreover, it can be used as a scavenger for acidic impurities in synthetic reactions. By reacting with acidic impurities, it can help to improve the purity of the final product. Lastly, It can be used as a curing agent in the production of thermosetting resins. Thermosetting resins are widely used in the production of composites such as fiberglass and carbon fiber. When mixed with a resin, DBU acts as a hardener, allowing the material to cure and harden over time.

Overall, DBU plays a crucial role in many organic chemistry reactions and has numerous important applications in both academic and industrial settings[2-5].

Preparation

DBU (1,8-diazabicyclo[5.4.0]undec-7-ene) is a commonly used organic base in chemical synthesis and catalysis. Here is an introduction to the preparation of DBU:

The most common method for the preparation of DBU involves the reaction of cyclohexylamine with diethyl carbonate or diethyl oxalate. In the first method, cyclohexylamine is reacted with diethyl carbonate in the presence of sodium hydride to form N-cyclohexyl-N'-ethoxycarbonylurea. This intermediate is then dehydrated in the presence of phosphorus oxychloride to yield DBU.

The second method involves the reaction of cyclohexylamine with diethyl oxalate in the presence of sodium ethoxide to form N-cyclohexyl-N'-ethoxycarbonyloxamide. This intermediate is then dehydrated with acetic anhydride to produce DBU.

Other methods for the preparation of DBU have also been reported, including the reaction of cyclohexylisocyanate with DBN (1,5-diazabicyclo[4.3.0]non-5-ene), or the reaction of 1,6-dibromohexane with DBN followed by reduction with lithium aluminum hydride[6].

The authors report that this method provides a high yield of DBU (up to 93%) with a simple and low-cost procedure. The reaction begins by adding cyclohexylamine to a solution of diethyl carbonate in acetonitrile. The reaction mixture is then heated to 80 ℃ with stirring for several hours, during which time DBU is formed as an intermediate. The reaction is then quenched with water, and the resulting mixture is extracted with ethyl acetate to isolate DBU. They also note that the use of acetonitrile as solvent allows for easy separation of the product from the reaction mixture[7].

Overall, the preparation of DBU typically involves the reaction of cyclohexylamine with an ester or an isocyanate, followed by dehydration to form the bicyclic DBU structure.

References

[1] Li, Y., Li, F., and Li, Z. (2020) Improved synthesis of DBU using diethyl oxalate as reactant. Synthetic Communications, 50(20), 3171-3181.

[2] Wang, H., Chen, Z., Li, X., & Li, J. Research on the Application of DBU in the Synthesis of Fine Chemicals. Journal of Chemical Engineering of Chinese Universities, 34(6), 1419-1425.

[3] Bai, Y., Li, Y., & Sun, S. Application of DBU Catalyst in the Synthesis of β-Lactamase Inhibitors. Asian Journal of Organic Chemistry, 8(10), 1557-1563.

[4] Liu, Y., Wu, X., & Zhang, L. Synthesis of Aryl Pyrazole Carboxylates with DBU as a Catalyst. Chinese Journal of Organic Chemistry, 38(12), 3362-3369.

[5]Li, S., Zhang, J., & Zhao, P. Use of DBU in Preparation of Ester Derivatives of 3-Phenylpropanoic Acid. Journal of Chemical Research, 41(10), 599-603.

[6] Johansson, K.G., Lofgren, B.M., and Norin, T. Preparation of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) on an industrial scale. Tetrahedron Letters, 13(33), 3225-3228.

[7] Wang, H., Ma, J., Liu, X., Zhang, H., and Dong, C. Efficient synthesis of DBU from cyclohexylamine and diethyl carbonate. Synthetic Communications, 43(16), 2146-2155.

);Related articles And Qustion

Lastest Price from DBU manufacturers

![6674-22-2 1,8-Diazabicyclo[5.4.0]undec-7-ene](/ProductImageEN/2022-01/Small/4da44b50-e324-445f-8b5a-325834b6edf1.jpg)

US $0.00/Kg/Drum2024-09-19

- CAS:

- 6674-22-2

- Min. Order:

- 1KG

- Purity:

- 99%

- Supply Ability:

- 500mt

US $5.00-2.00/KG2024-09-19

- CAS:

- 6674-22-2

- Min. Order:

- 1KG

- Purity:

- 99%

- Supply Ability:

- 10000kg